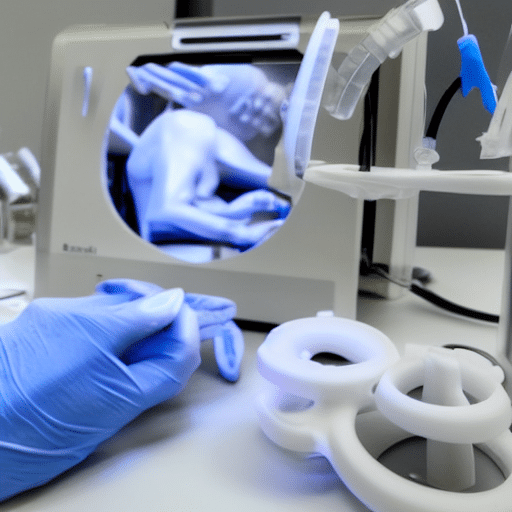

The use of 3D printing technology in medicine is growing rapidly, and the benefits of this innovative technology are already apparent. In this article, we will explore the impact of 3D printing on medical devices and how it is revolutionizing healthcare.

Introduction

Medical devices are an essential aspect of modern healthcare, with a wide range of devices used to diagnose, treat, and monitor patients. However, the production of these devices can be time-consuming and costly, particularly for unique or custom devices. This is where 3D printing technology comes in, offering an efficient and cost-effective solution for the production of medical devices.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by building up layers of material. This process allows for the creation of complex geometries and intricate designs that may be impossible or difficult to achieve with traditional manufacturing techniques.

Advantages of 3D Printing in Medical Devices

The use of 3D printing technology in medical devices offers several advantages, including:

Customization

One of the most significant advantages of 3D printing is the ability to create custom devices. This is particularly useful in medical applications, where patients may require unique devices tailored to their specific needs.

Reduced Costs

Traditional manufacturing methods often require expensive tooling and machining, making the production of small quantities of custom devices cost-prohibitive. 3D printing eliminates the need for these expensive tooling costs, making it a more cost-effective solution for small production runs.

Faster Production

3D printing allows for rapid prototyping and production of medical devices, significantly reducing the time it takes to bring a device to market. This is particularly important in the medical field, where new devices may be required urgently.

Improved Design

The ability to create complex geometries and intricate designs with 3D printing allows for the production of more effective and efficient medical devices.

Applications of 3D Printing in Medical Devices

The use of 3D printing technology in medical devices has a wide range of applications, including:

Prosthetics

3D printing allows for the production of custom prosthetic devices, which can be tailored to fit the patient’s specific needs. This offers a significant improvement over traditional prosthetics, which may be uncomfortable or ill-fitting.

Implants

3D printing allows for the creation of custom implants, such as hip or knee replacements. These implants can be tailored to fit the patient’s anatomy precisely, resulting in improved outcomes and reduced complications.

Surgical Tools

3D printing allows for the creation of surgical tools tailored to the specific needs of a surgical procedure. These tools can be designed to be more ergonomic, efficient, and effective than traditional surgical tools.

Tissue Engineering

3D printing can be used to create scaffolds for tissue engineering, allowing for the production of tissues and organs for transplantation.

Challenges and Limitations of 3D Printing in Medical Devices

While 3D printing technology offers significant advantages in the production of medical devices, there are also several challenges and limitations, including:

Material Limitations

The materials used in 3D printing can be limited, particularly when it comes to medical-grade materials. This can limit the types of devices that can be produced using 3D printing.

Regulatory Approval

The regulatory approval process for 3D-printed medical devices can be complex and time-consuming, which may limit the adoption of this technology in the medical field.

Quality Control

Ensuring the quality and consistency of 3D-printed medical devices can be challenging, particularly when it comes to complex geometries or intricate designs.

Future of 3D Printing in Medical Devices

One area where 3D printing is already making a significant impact is in the production of medical implants. In recent years, we have seen an increase in the use of 3D-printed implants, particularly in orthopaedic surgery. These implants offer several advantages over traditional implants, including improved fit and reduced risk of complications.

Another area where 3D printing is showing promise is in the production of personalized medicine. By using 3D printing to create custom drug delivery devices, such as implants or inhalers, doctors can tailor treatment to the individual needs of each patient.

In conclusion, 3D printing technology is revolutionizing the production of medical devices, offering faster, more cost-effective, and more personalized solutions. While there are still challenges to be overcome, the potential benefits of this technology are significant and far-reaching. As 3D printing continues to develop, we can expect to see it play an increasingly important role in healthcare, improving outcomes for patients around the world.

FAQs

- Is 3D printing safe for medical devices?

Yes, 3D printing can be safe for medical devices. However, it is essential to ensure that the materials used in 3D printing are appropriate for medical use and that the devices are produced to the required quality standards.

- How long does it take to 3D print a medical device?

The time it takes to 3D print a medical device depends on several factors, including the size and complexity of the device and the type of 3D printing technology used. However, 3D printing can significantly reduce the time it takes to produce a medical device compared to traditional manufacturing methods.

- Can 3D printing be used for surgical implants?

Yes, 3D printing can be used to produce surgical implants, including hip and knee replacements. By customizing the implants to fit the patient’s anatomy precisely, 3D printing can improve outcomes and reduce complications.

- What are the regulatory challenges associated with 3D-printed medical devices?

The regulatory approval process for 3D-printed medical devices can be complex and time-consuming. To ensure patient safety, 3D-printed medical devices must meet the same regulatory requirements as traditionally manufactured devices.

- What is the future of 3D printing in healthcare?

The future of 3D printing in healthcare looks bright, with the potential for personalized medicine, improved surgical outcomes, and more efficient production of medical devices. As the technology continues to develop, we can expect to see even more exciting applications of 3D printing in healthcare.